As we know the 0 curve on the 3MA CDI is somewhat spectacular.

In my first tests you can see the bike does not give you more power when using the 0 curve

The idea now is to shorten the 3MA1 pipes to let them peek at 10.800 a 11000 rpm (where it is 14 degrees using the 0 curve)

Shortened the exhaust pipes with 30MM

Stock 3MA1 pipes are close to 945mm long

Now shortened (with the 30mm) total length becomes 915mm

This hopefully will bring peek power from 10.150rpm (stock pipe) to a 10.800rpm.

The plan on paper

Her we go.

Stock pipes on the bike

The (original) pipes on the floor

Marked the place where to cut (30mm)

Two pipes with the cutout pieces

Also cut the mounting point's, to re-weld later

Before welding (tack the pipes), plugged of the exhausts.

Don't want any welding bulb's coming in my exhaust (again)

The two shortened pipes welded

Not my best welding, but it definitively will hold

Re-welded the mounting points

When all mounted back, its tight but seems to fit nice

First impression is good.

EGT sensors welded and mounted, As tight as possible to the piston. (shortest distance)

Both Exhausts mounted back with the two EGT sensors

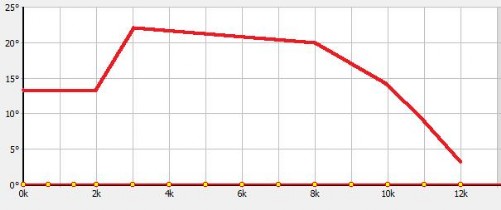

Had some time to test the 0 curve and 1 curve. The shortened pipes peek around the 11.000rpm mark, so that turns out to be perfect.

Her is the full throttle curve, kicking out a 60,8 HP at 10.686rpm

Its a bid more than the 60,3HP with the stock pipes.

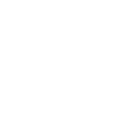

The stock pipes

Here is the run with the closed throttle curve, a nice 64,7HP at 10.732rpm

Peeking at +/-11.000rpm where the pipe's where Shortened for.

Here you see the difference between the closed and full ignition curve.